What Are Manufacturing Apps?

Manufacturing applications are specialized software solutions that are designed specifically to simplify and optimize manufacturing processes.

These apps integrate diverse prospects of production, from inventory management to quality control that provides real-time monitoring and control capabilities.

They assist businesses automate workflows, managing resources, making data-driven decisions, and tracking production metrics. These digital tools can be tailored to specific manufacturing necessities and can integrate with the existing systems and equipment.

Benefits of Manufacturing Apps

Manufacturing applications have revolutionized the industrial sector by introducing digital transformation and automation into conventional processes. The key benefits these apps offer to the various manufacturing businesses are as follows:

1. Enhanced Operational Efficiency

Digital workflows and automated processes significantly reduce manual tasks and paperwork. Real-time monitoring and control capabilities allow for quick response to production issues, while streamlined operations reduce bottlenecks and optimize resource utilization across the manufacturing floor.

2. Improved Quality Control

Sophisticated quality management features help maintain consistent product quality through automated checks and inspections. Digital documentation and tracking systems ensure adherence to industry standards, whereas real-time alerts prevent quality issues before they intensify.

3. Cost Reduction

Smart resource allocation and inventory management reduce waste and optimize material usage. Predictive maintenance capabilities reduce equipment downtime and repair costs, whereas automated processes decrease labor costs and human error-related expenses.

4. Data-Driven Decision Making

Comprehensive analytics and reporting tools provide beneficial insights into production performance. Real-time data collection and analysis allow for informed decision-making, whereas predictive analytics help forecast maintenance needs and production demands.

5. Supply Chain Optimization

Integrated supply chain management features provide complete visibility into inventory levels and supplier relationships. Automated ordering systems prevent stockouts, whereas real-time tracking ensures seamless material flow throughout the production process.

Main Purpose of a Manufacturing App

The primary purpose of a manufacturing application is to digitize and optimize the overall manufacturing process. It basically serves as a central platform for controlling, monitoring, and enhancing production operations while ensuring quality standards are maintained.

These apps bridge the gap between different manufacturing elements, allowing for smooth communication and data flow across different departments, ultimately leading to increased productivity and reduced operational costs.

System Requirements For Using A Manufacturing App

Manufacturing apps typically require stable internet connectivity, compatible hardware devices, and sufficient processing power. The system should support the latest operating systems and have adequate storage capacity for data management.

Mobile devices, tablets, or computers used should meet minimum specifications for smooth operation. Cloud-based solutions may need reliable network infrastructure and secure access protocols.

Key Features For Manufacturing App Development

Creating a robust manufacturing mobile application requires crucial features that ensure optimal functionality and user experience. These features form the foundation of an essential manufacturing management solution. Below is the list of the must-have features for manufacturing app development:

1. Real-time Monitoring and Analytics

This feature allows for continuous tracking of production processes, resource utilization, and equipment performance in real time.

Sophisticated analytics tools process collected data in order to generate actionable insights, helping manufacturers identify trends, optimize operations, and predict maintenance needs through data-driven decision-making.

2. Inventory Management System

The inventory management system is a feature that maintains accurate records of raw materials, finished products, and work-in-progress items.

It includes automated stock-level monitoring, barcode scanning capabilities, reorder point notifications, and inventory forecasting tools in order to ensure optimal stock levels and prevent production delays.

3. Quality Control Module

The quality control module is an enhanced feature that enforces systematic and effective quality checks throughout the production process.

It generally includes automated inspection protocols, quality metrics monitoring, defect tracking, and compliance documentation tools in order to maintain consistent product quality and fulfill industry standards.

4. Production Planning and Scheduling

This feature optimizes production schedules by considering resource availability, order priorities, and machine capacity.

It includes visual planning tools, real-time adjustments, and automated scheduling algorithms in order to maximize efficiency and meet delivery deadlines.

5. Supply Chain Integration

Supply chain integration is a feature that connects manufacturers with distributors and suppliers through a unified platform.

It generally includes supplier evaluation tools, order management, automated procurement processes, and logistics tracking in order to ensure seamless material flow and on-time deliveries.

6. Machine Integration and IoT Connectivity

Machine integration and IoT connectivity are robust features that enable smooth communication between manufacturing equipment and the application through IoT sensors.

It includes equipment monitoring, performance tracking, and predictive maintenance alerts for improved operational effectiveness.

7. Employee Management Portal

This feature simplifies workforce management with digital time tracking, performance monitoring, and skill mapping tools.

It includes training management, communication, and shift scheduling features in order to optimize workforce productivity and utilization.

8. Reporting and Documentation

Reporting and documentation are essential features that generate comprehensive reports on production metrics, resource utilization, and quality parameters.

It basically includes tailored dashboards, document management, automated report generation, and data export capabilities for informed decision-making.

How to Develop a Manufacturing App?

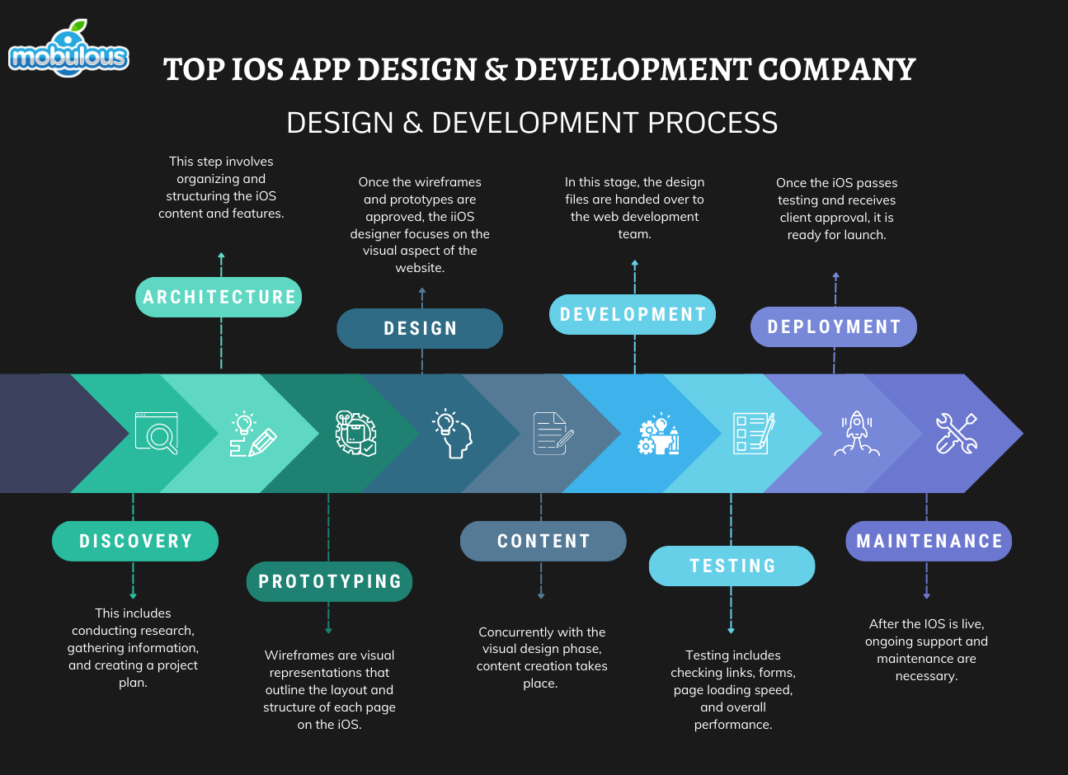

Creating a manufacturing application requires a systematic approach and comprehensive methodology that ensures all requirements are fulfilled and the final product delivers optimal performance. Here’s a detailed manufacturing application development process:

1. Initial Research and Planning

The process starts with market research, identifying the target audience, and understanding industry necessities. This phase generally includes feature prioritization, competitor analysis, and creating a detailed project roadmap with clear milestones and deliverables.

2. Requirements Gathering and Analysis

Detailed requirements are collected from stakeholders, including functional specifications, integration needs, and technical requirements. This generally involves documenting user stories, demonstrating the system architecture, and creating wireframes.

3. Technology Stack Selection

Appropriate technologies are selected depending on project requirements and scalability needs. This includes choosing robust development frameworks, tech stack, programming languages, integration tools, cloud services, APIs, and database systems that best suit the manufaturing environments.

4. Design and Prototyping

User interface and experience designs are created by emphasizing ease of use and functionality. This phase typically includes creating interactive prototypes, refining designs, and seeking user feedback before the actual development begins.

5. Development and Testing

The app is created by following the best practices and rigorous testing protocols. This stage includes continuous integration testing, iterative development cycles, security testing, and performance optimization in order to ensure reliability.

6. Deployment and Maintenance

The app is deployed across target platforms with proper documentation and training materials, including regular updates, technical support, ongoing maintenance, and performance monitoring in order to ensure smooth and seamless operation.

Right Technology Stack For Manufacturing App Development

Selecting the most appropriate technology stack is essential for building a robust manufacturing application that is effective, future-proof, and highly scalable. The tech stack comprises the frameworks, programming languages, tools, and platforms used to create the application. Let’s have a comprehensive overview of the right technology stack for manufacturing app development:

1. Frontend Technologies

The front end is the user interface of the app.

- Frameworks/Libraries: React.js, Angular.js, or Vue.js for responsive and interactive user experiences.

- Languages: HTML5, CSS3, and JavaScript for basic structure, style, and functionality.

- Tools: Bootstrap or Material UI for pre-designed UI components.

2. Backend Technologies

The backend is the server-side logic managing data and functionality.

- Languages: Node.js, Python (Django, Flask), Java (Spring), or .NET Core.

- Frameworks: Express.js, Laravel, or Ruby on Rails for faster development.

- Database: Use SQL databases (PostgreSQL, MySQL) for structured data and NoSQL databases (MongoDB, Cassandra) for unstructured data.

3. Mobile App Development

For mobile manufacturing apps, ensure compatibility with different platforms.

4. Cloud Platforms

For scalability and real-time operations:

- AWS, Microsoft Azure, or Google Cloud Platform provide reliable hosting, computing, and analytics tools.

- Cloud databases like Firebase can enable seamless synchronization and offline capabilities.

5. IoT Integration

IoT is essential for real-time monitoring and smart devices.

- Protocols: MQTT, CoAP, or AMQP for secure communication.

- Platforms: AWS IoT Core, Azure IoT Hub, or Google Cloud IoT Core.

6. Data Analytics and AI

For actionable insights and predictive maintenance:

- Big Data Tools: Hadoop, Apache Spark for large-scale data processing.

- AI/ML Libraries: TensorFlow, and PyTorch for machine learning capabilities.

7. Security and Compliance

Ensuring data integrity and compliance with industry standards:

- Use HTTPS, SSL/TLS encryption, and OAuth2 for secure data transmission.

- Compliance frameworks like ISO 27001 or GDPR (if applicable).

8. DevOps and CI/CD Tools

For seamless updates and maintenance:

- Tools like Jenkins, Docker, and Kubernetes for continuous integration and deployment.

Different Platforms For Manufacturing App Development

Manufacturing apps can be developed for different platforms in order to ensure functionality and accessibility across multiple devices. Each platform offers unique advantages for manufacturing operations. Below is the comprehensive breakdown of the essential platforms for manufacturing application development:

1. iOS App Development

iOS application development provides a secure and stable platform for manufacturing apps with robust performance capabilities.

The platform offers excellent hardware integration, consistent user experience, and superior security features. Development follows strict guidelines ensuring high-quality applications that integrate seamlessly with other Apple devices and services.

2. Android App Development

Android application development offers flexibility and widespread device compatibility for manufacturing applications.

The platform provides extensive customization options, easier integration with various hardware devices, and support for diverse screen sizes. Android's open nature allows for deeper system integration and custom hardware connectivity.

3. Web App Development

Web application development provides platform-independent access to manufacturing systems through standard browsers.

They offer real-time data accessibility from any location, simplified deployment and updates, and seamless integration with existing web-based systems. Web apps eliminate the need for platform-specific installations while ensuring consistent functionality.

4. Cross-Platform App Development

Cross-platform app development enables the development of applications that work across multiple platforms with a single codebase.

This approach reduces development time and costs while maintaining consistent functionality across different devices. It provides excellent reach and accessibility while simplifying maintenance and updates.

How to Track Manufacturing KPIs Using The Manufacturing App?

Manufacturing apps provide powerful tools for monitoring and analyzing key performance indicators (KPIs) essential for operational success. The following points outline the core methods for effective KPI tracking:

- Real-Time Dashboard Monitoring: Track live production metrics through interactive dashboards.

- Automated Data Collection: Gather data automatically from connected machines and sensors.

- Custom KPI Setup: Configure specific KPIs based on business objectives.

- Performance Alerts: Receive notifications when KPIs deviate from targets.

- Historical Analysis: Compare current performance against historical data.

- Report Generation: Create detailed reports for stakeholder review.

Are There SDKs Provided For Customizing The Manufacturing App?

Software Development Kits (SDKs) are available for customizing manufacturing applications. These SDKs include APIs, development tools, documentation, and code samples that enable developers to modify and extend app functionality.

They support various programming languages and platforms, allowing integration with different manufacturing systems. The SDKs provide modules for IoT connectivity, data analytics, user interface customization, and system integration.

What Security Protocols Are Implemented in The Manufacturing App?

Manufacturing apps require robust security measures in order to safeguard sensitive operational data and ensure system integrity. The key security protocols implemented in the apps are mentioned below comprehensively:

1. Data Encryption

Advanced encryption protocols protect data both at rest and in transit. Multiple encryption layers secure sensitive manufacturing information, while SSL/TLS protocols ensure secure data transmission. End-to-end encryption safeguards communication between different app components and user devices.

2. Access Control Management

Role-based access control systems manage user permissions and system access. Multi-factor authentication verifies user identities, while detailed access logs track system usage. Granular permission settings ensure users can only access authorized information and functions.

3. Regular Security Audits

Automated security scans and periodic vulnerability assessments identify potential threats. Regular penetration testing evaluates system defenses, while compliance checks ensure adherence to industry security standards. Continuous monitoring detects and responds to security incidents.

4. Secure Data Backup

Automated backup systems regularly save critical manufacturing data to secure locations. Redundant storage systems prevent data loss, while encrypted backup protocols protect sensitive information. Disaster recovery plans ensure business continuity in case of system failures.

Can The Manufacturing App Be Integrated With The User’s Existing ERP System?

Yes, manufacturing apps can integrate with existing Enterprise Resource Planning (ERP) systems through specialized APIs and integration protocols.

The integration process includes data synchronization, workflow automation, and real-time information exchange between systems.

Custom connectors and middleware solutions ensure smooth communication while maintaining data integrity and system performance. Professional implementation teams handle the integration process.

Will The Manufacturing App Support Future Technological Upgrades Like AI or IoT Enhancements?

Manufacturing apps are designed with scalability and future technological advancement in mind. The modular architecture allows for seamless integration of new technologies like artificial intelligence, machine learning, and advanced IoT capabilities.

Regular updates and platform enhancements ensure compatibility with emerging technologies and industry standards. The development framework supports continuous improvement and feature additions while maintaining system stability.

Does The Manufacturing App Support Predictive Maintenance Features?

Yes, manufacturing apps incorporate advanced predictive maintenance capabilities using machine learning algorithms and real-time data analysis.

The system monitors equipment performance, analyzes historical data, and identifies potential issues before they cause breakdowns.

It tracks maintenance schedules, equipment health metrics, and performance patterns to predict maintenance needs. The app generates automated alerts, maintenance recommendations, and detailed reports to optimize equipment reliability and reduce downtime.

Does The Manufacturing App Integrate With IoT Devices For Real-Time Monitoring?

Yes, manufacturing apps seamlessly integrate with various IoT devices including sensors, smart equipment, and monitoring systems. The integration enables real-time data collection, automated alerts, and continuous performance monitoring.

The system supports multiple IoT protocols and can connect with various industrial sensors to track parameters like temperature, pressure, vibration, and production metrics.

Cost of Manufacturing App Development

The cost of manufacturing app development is around $20,000 to $ 150,000 and more. However, this cost range varies based on complexity, features, and customization requirements. Basic applications typically range from $25,000 to $50,000, while complex enterprise solutions can cost $150,000 or more.

Factors affecting cost include custom integrations, IoT connectivity, security requirements, platform choice, selection of the technology stack, and the expertise of the manufacturing app development company. Additional costs may include maintenance, updates, training, and ongoing support services.

Timeline of Manufacturing App Development

Manufacturing app development typically takes 4 to 8 months, depending on the project’s scope, complexity, and the expertise of the manufacturing app development company.

The timeline includes requirements gathering (2 to 3 weeks), design phase (3 to 4 weeks), development (12 to 16 weeks), testing (4 to 6 weeks), and deployment (2 to 3 weeks). Complex integrations or custom features may extend the timeline.

Benefits of Partnering With The Top Manufacturing App Development Company

Choosing the best manufacturing app development company is essential for building a successful manufacturing app. The key advantages of collaborating with a leading app development company are mentioned below comprehensively:

1. Industry Expertise and Experience

Professional developers at a leading manufacturing app development company brings extensive knowledge of manufacturing processes and industry standards.

Their experience across various manufacturing sectors ensures optimal solution design, efficient implementation strategies, and adherence to best practices. They understand specific challenges and provide proven solutions based on successful past projects.

2. Advanced Technical Capabilities

A renowned manufacturing app development company employs cutting-edge technologies and development methodologies.

Their technical expertise covers IoT integration, cloud computing, artificial intelligence, and advanced analytics. The team's diverse skill set ensures comprehensive solution development using the latest tools and frameworks.

3. Customization and Scalability

A well-established manufacturing app development company provides tailored solutions that perfectly match specific manufacturing requirements.

They design scalable applications that can grow with business needs, incorporate future technological advances, and adapt to changing industry demands while maintaining optimal performance levels.

4. Ongoing Support and Maintenance

A professional manufacturing app development company offers comprehensive post-deployment support services.

They provide regular updates, technical maintenance, security patches, and performance optimization. Their dedicated support teams ensure smooth operation and quick resolution of any issues that arise.

Steps to Hire the Best Manufacturing App Development Company

Finding the right manufacturing app development company requires careful evaluation and consideration. Follow the below-mentioned essential steps to select the most suitable manufacturing app development company:

1. Research and Shortlisting

Conduct thorough market research to identify the potential manufacturing app development company. Review its portfolios, client testimonials, and industry experience. Shortlist the firm based on its expertise in manufacturing solutions and technical capabilities.

2. Technical Evaluation

Assess the manufacturing app development company's technical expertise, development methodologies, and technology stack. Review their past projects in the manufacturing sector, examine their approach to quality assurance, and evaluate their understanding of industry-specific requirements.

3. Project Planning Discussion

Arrange detailed discussions about project requirements, timelines, and deliverables of the manufacturing app development company. Evaluate their ability to understand specific needs, their proposed solution approach, and their communication style during preliminary meetings.

4. Cost and Contract Review

Review cost proposals from the potential manufacturing app development company while considering the value offered. Examine contract terms, including project milestones, payment schedules, and maintenance agreements. Ensure all requirements and deliverables are clearly documented.

5. References and Verification

Contact previous clients to verify the manufacturing app development company's performance and reliability. Review case studies of similar projects, check industry certifications and evaluate their track record in delivering manufacturing solutions on time and within budget.

Contact us

Contact us